Vicmarc Eccentric Chuck

The Vicmarc Eccentric Chuck expands the possibilities of woodturning by allowing you to change the turning axis of your workpiece. Vicmarc offers a variety of accessories for the chuck, but what you will need depends on what you want to do. That being said, all the different options can be very confusing if you're not familiar with the chuck.

Hopefully this guide will answer any questions about the Vicmarc Eccentric Chuck. If not, give us a call at 702-871-0722 and we will be happy to walk you through it.

Woodturning is, by nature, a dangerous art form. Eccentric turning further compounds the danger by purposely making the workpiece off-balance. The larger the piece, the harder it will be to control. That being said, I don't recommend this chuck for beginners. Wait at least until you are comfortable with conventional turning. When you do graduate to eccentric turning, take it slow. It can be difficult to determine exactly where the edge is, and a tool catch is much more likely. A safety drive is definitely a good idea.

Any time you're turning something off-balance, you should attempt to counter balance the lathe as much as possible. There is much debate in the woodturners forums about bolting down your lathe, so I hesitate to make a recommendation there, but trust me when I say you do not want your lathe walking away from you while you're turning.

To simplify, an axis is the imaginary line on which your work piece rotates, on a lathe this would be the horizontal line from the center point of your spindle.

let's define multi-axis as the axis of the piece rotating at an angle to the axis of the lathe, and off-axis as the axis of the piece being parallel to the axis of the lathe.

First, there are two different versions available: the #2 and #3. The Vicmarc Eccentric chuck #2 will allow to do multi-axis turning. The Vicmarc Eccentric chuck #3 allows to turn off-axis, and with the addition of a ball adaptor you can also do multi-axis turning.

EDIT: There is now an Eccentric chuck #4 as well. It is very similar in function to the #3, but it is smaller and does not include counter weights. Because of the more simplistic design it is a bit more budget friendly, but the lack of counter balancing also means it will be less effective on heavier pieces. I won't go into detail since the info below for the #3 chuck all applies to the #4 as well.

The Vicmarc Eccentric Chuck #2

The Vicmarc Eccentric Chuck #2 allows you to tilt your workpiece along the Z axis. You can buy it 3 different ways. All three are essentially the same, the only difference is how it attaches to the lathe.

The first option is the direct thread version, which will screw directly onto a 1-1/4"x8 spindle (a common spindle size for full size lathes sold in the US).

The second option is for the lathes that don't have an 1-1/4"x8 Spindle, or if you want to use it on more than one lathe. If you have a mini lathe, a Shopsmith, or an imported lathe, odds are you will need an adapter. The #2 chuck is also sold with the same thread size as Vicmarc's VM120 Chuck, so you can adapt it with a VM120 insert.

The third option is to just buy the ball adapter and a Vermec CHU-889 chuck pickup. The dovetailed recess on the back allows you to use your 4-jaw chuck in expansion mode, essentially transforming it into an eccentric chuck.

Now you need a ball. These are what you will use to mount your workpiece to the chuck, and tilting the ball in the socket is what allows you to change the Z-axis. The ball is offered with 10, 22, and 40mm holes for mounting different sizes of work. These will be used like a jam chuck, meaning you will cut a tenon on your workpiece and press-fit it into the ball. The size of the tenon is crucial since it will be holding the workpiece to the chuck. A gauge is provided with the #3 chuck, you'll have to purchase it separately for the #2. Obviously a good set of calipers will work as well.

If you prefer to use a faceplate, a threaded ball is available that a 90mm (3-1/2") faceplate screws into.

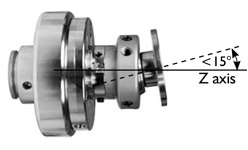

To tilt the Z-axis, insert the ball into the socket. Insert your tenon tightly into the ball, then rotate the ball to the desired angle (up to 15°). The ball adapter has several set screws to lock the ball into place at varying angles. There are indexing lines on the ball to help determine the angle.

The Vicmarc Eccentric Chuck #3

This is the Vicmarc Eccentric Chuck #3. it includes:The chuck comes standard with a 40mm (1.57") cup chuck to mount work . The cup chucks are available in 22, 40, and 52mm. They are similar to the ball in that you cut a tenon and press-fit it in, but the cup chuck does not allow you to tilt along the Z-axis.

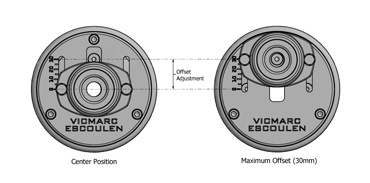

This chuck by itself will only allow you to adjust the axis on a parallel plane, meaning you can only move off axis.

This is where the ball and ball adapter come into play. The ball adapter is basically the #2 Eccentric chuck, but without the body that attaches it to the lathe. Instead it attaches to the #3 chuck, allowing multi axis turning. Now not only can you adjust off-axis , you can also tilt the workpiece as well.

Hopefully this guide answers any questions you have about the Vicmarc Eccentric Chuck. If not, please feel free to contact us either at 1-800-779-7458 (Local 702-871-0722) or by email at info@woodworkersemporium.com

Recent Posts

-

Vicmarc Eccentric Chuck

The Vicmarc Eccentric Chuck expands the possibilities of woodturning by allowing you to change …Aug 17th 2018